Fused Deposition Modeling (FDM)

- FDM builds concept models, functional prototypes and end-use parts in standard, engineering-grade and high-performance thermoplastics. It’s the only professional 3D printing technology that uses production-grade thermoplastics, so parts are unrivaled in mechanical, thermal and chemical strength.

- FDM, a prominent form of rapid prototyping, is used for prototyping and rapid manufacturing. Rapid prototyping facilitates iterative testing, and for very short runs, rapid manufacturing can be a relatively inexpensive alternative.

Benefits

- FDM uses high-performance thermoplastics, the same strong materials used for injection molding.

- So they’re tough enough to endure heat, chemicals, humidity and mechanical stress.

DURABILITY

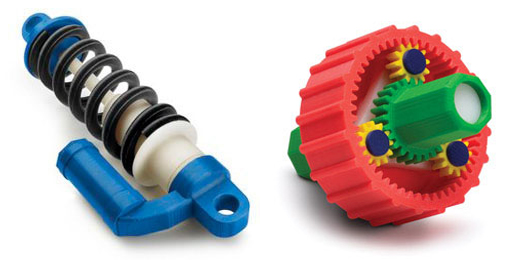

- Soluble support materials make it possible to build geometries that would be impossible with traditional manufacturing.

ACCURACY

- FDM produces parts with a level of consistency that’s more reliable than Stereolithography (SLA) and Selective Laser Sintering (SLS), which use resins that may depreciate over time.

- The technology is clean, simple-to-use and office-friendly Supported engineering-grade thermoplastics are mechanically and environmentally stable Complex geometries and cavities that would otherwise be problematic become practical with FDM technology.

REPEATABILITY

If not a registered user